Media Mixing |

|

|---|---|

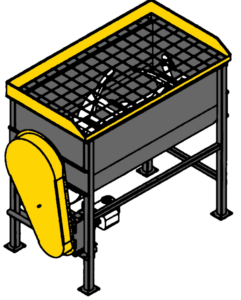

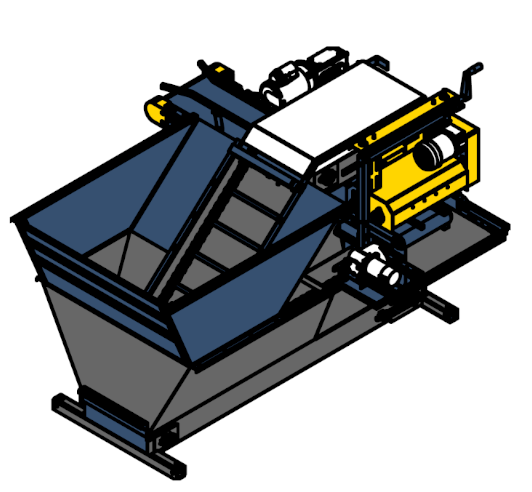

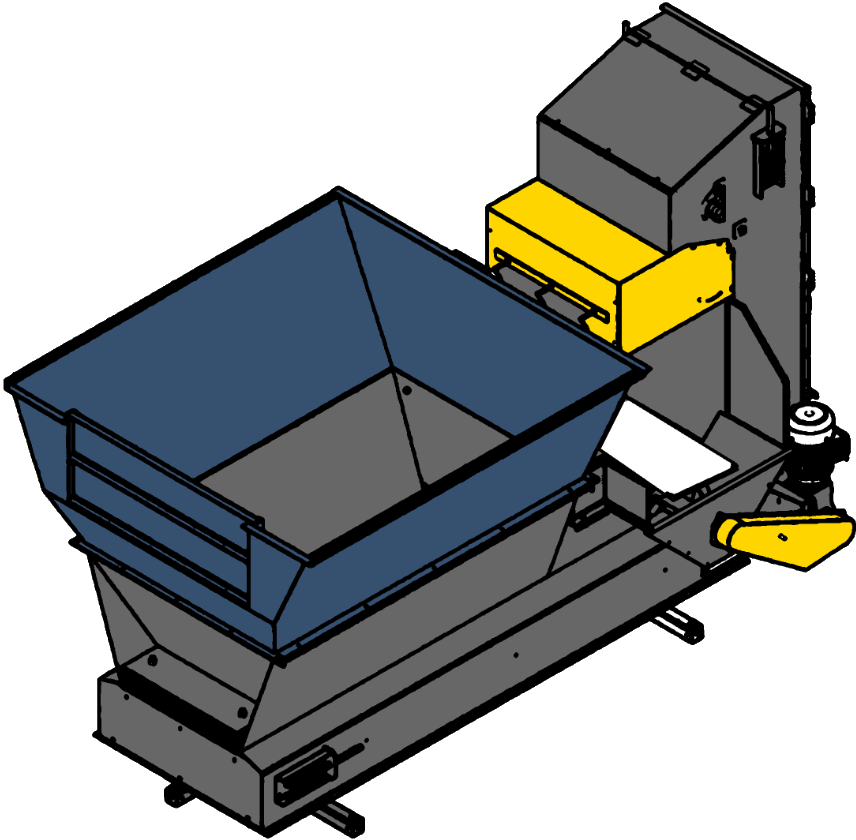

| 3403A 3/4 Yard Mixer |

| 1.5 HP Motor | |

| 3/4 Cubic Yard | |

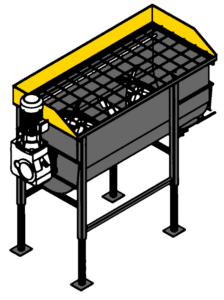

| 3413A 1 1/4 Yard Mixer |

| 5 HP Motor | |

| 1 1/4 Cubic Yard | |

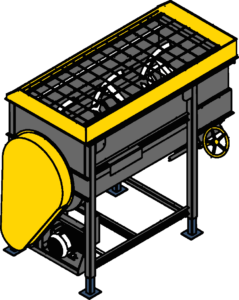

| 3423A 2-Yard Mixer |

| 7.5 HP Motor | |

| 2 Cubic Yard | |

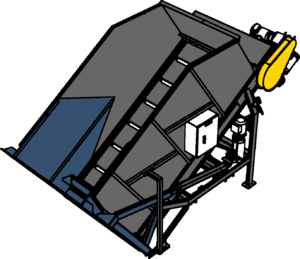

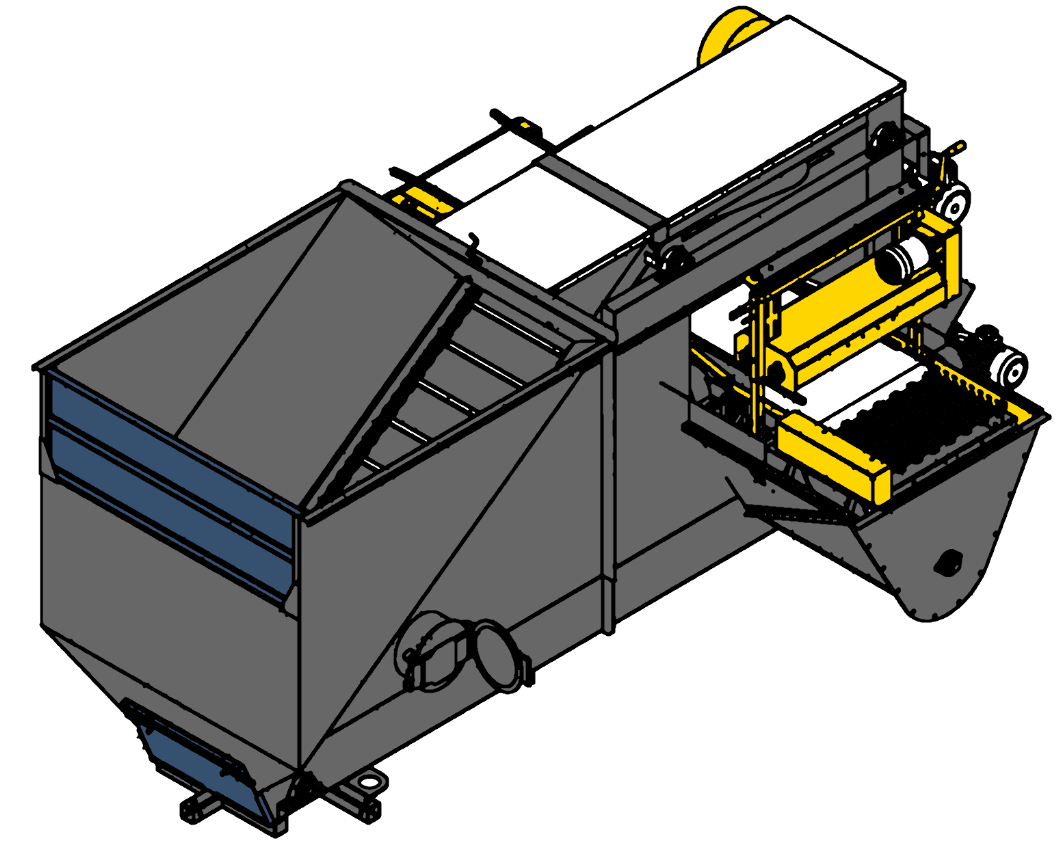

| 3538A Mini-Gobbler (Small Bale Processor |

| Holds up to 6 (3.8cf) compressed bales | |

| 15 cu. Yds per hour | |

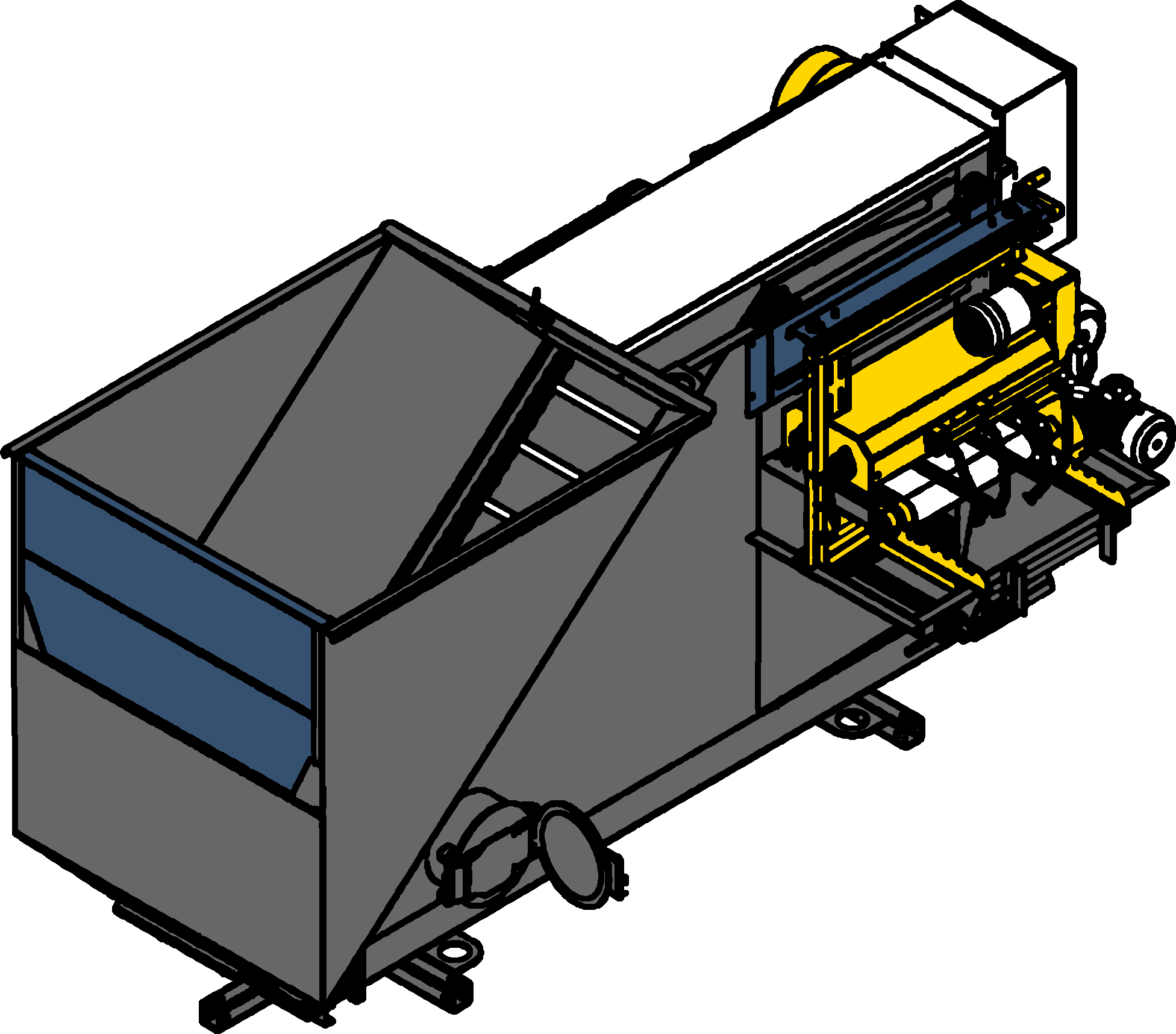

| 3561A Gobbler (Large Bale Processor) |

| 4'x4'x8' up to 135cf compressed bales | |

| 75 cu yds per hour | |

Flat and Pot Filling |

|

|---|---|

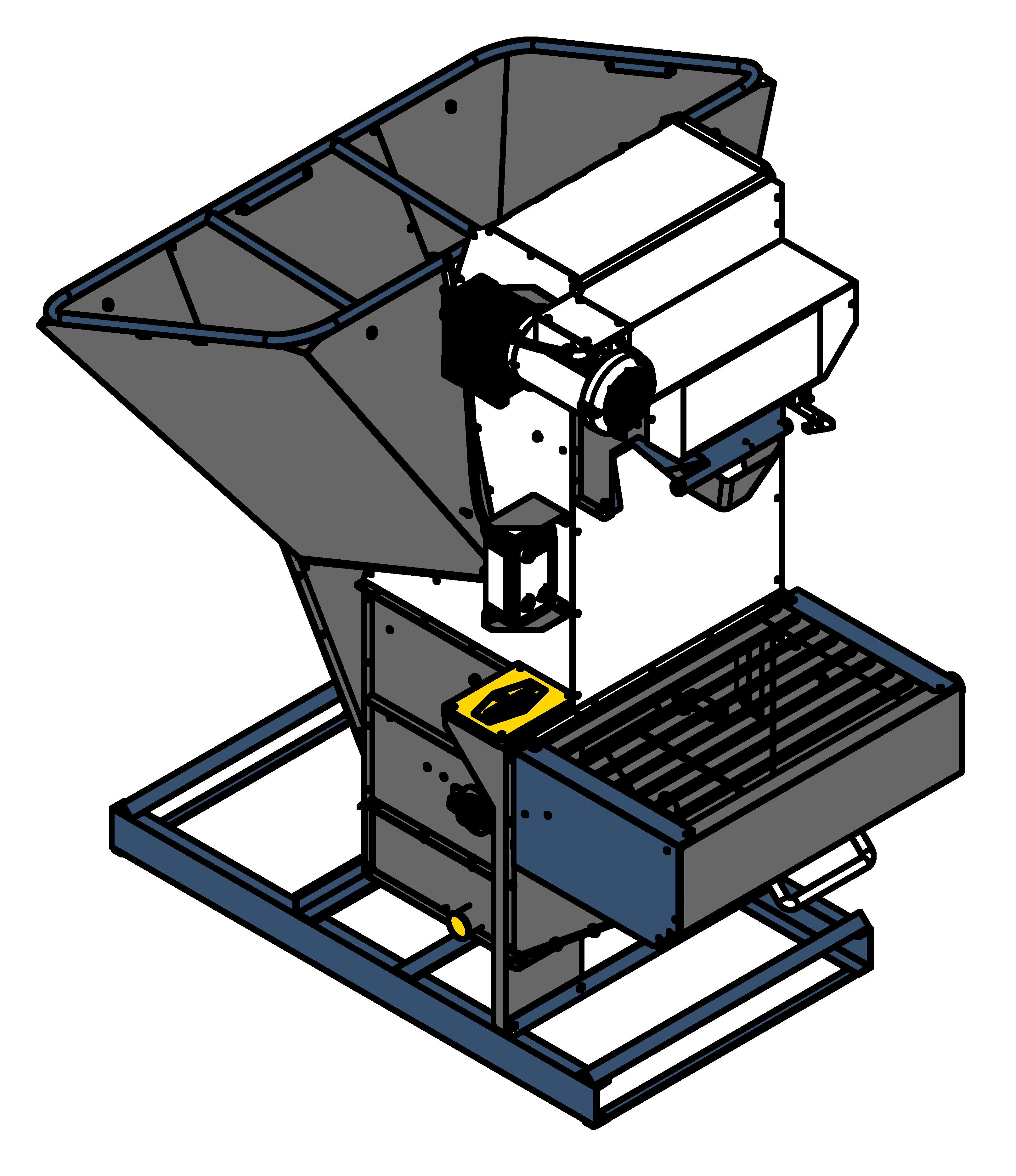

| 5110A A-Line Filler |

| 1/3 or 1 Yard Hopper | |

| 300 flats / Hour | |

| 12 gal/min | |

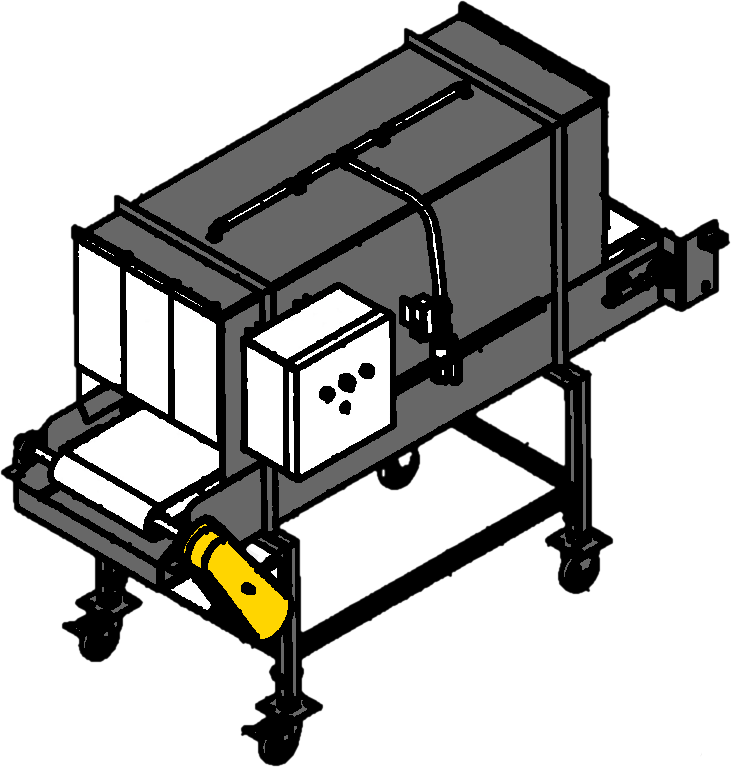

| 5332A Minor B Filler |

| 3/4 Yard Hopper | |

| 800 flats / hour | |

| 33 gal/min | |

| 5343A B-Line Filler |

| 1 1/2 Yard Hopper | |

| 1200 flats / hour | |

| 50 gal/min | |

| 5361A Super B Filler |

| 2 1/4 Yard Hopper | |

| 1800 flats / hour | |

| 74 gal/ min | |

| 5662A N-Line Filler |

| 4 Yard Hopper | |

| 2400 flats / hour | |

| 99 gal/min | |

Conveyors |

|

|---|---|

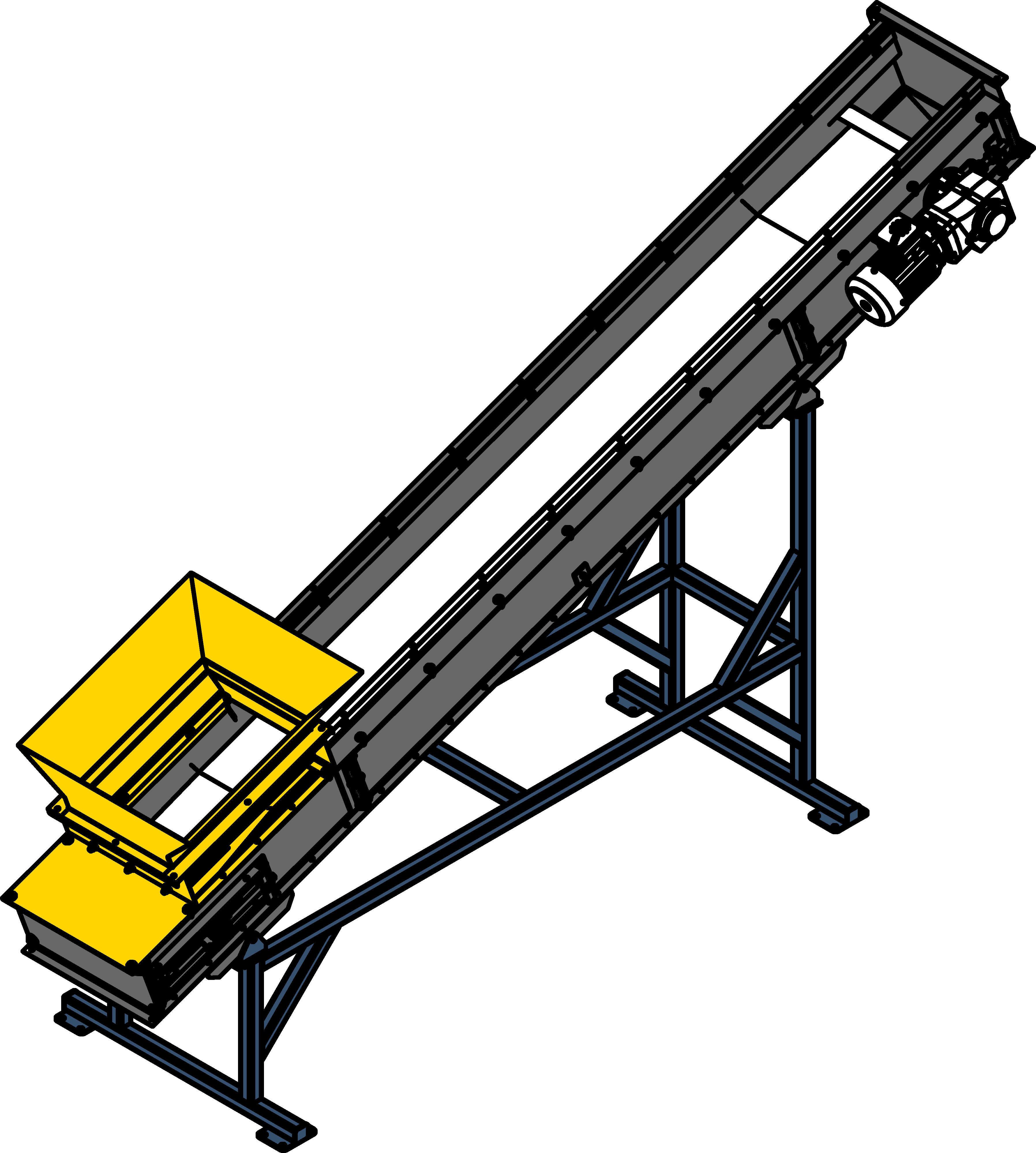

| 4300A Horizontal Soil Conveyor |

| 16“ Wide Trough Belt | |

| 6ft, 12ft, 24ft, 30ft Lengths | |

| 50 Cu. Yd/Hour | |

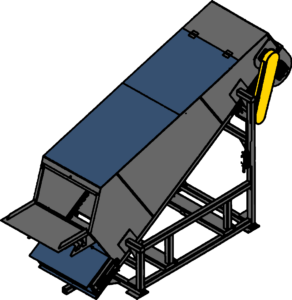

| 4310A Lifting Soil Conveyor |

| 16“ Wide Trough Belt | |

| 6ft, 12ft, 24ft, 30ft Lengths | |

| 50 Cu. Yd/Hour | |

| 4100A Modular Conveyor |

| 10" or 15" Wide Belts | |

| 5ft, 10ft, 15ft, 20' Sections | |

| Connectable, Reversable | |

Extras |

|

|---|---|

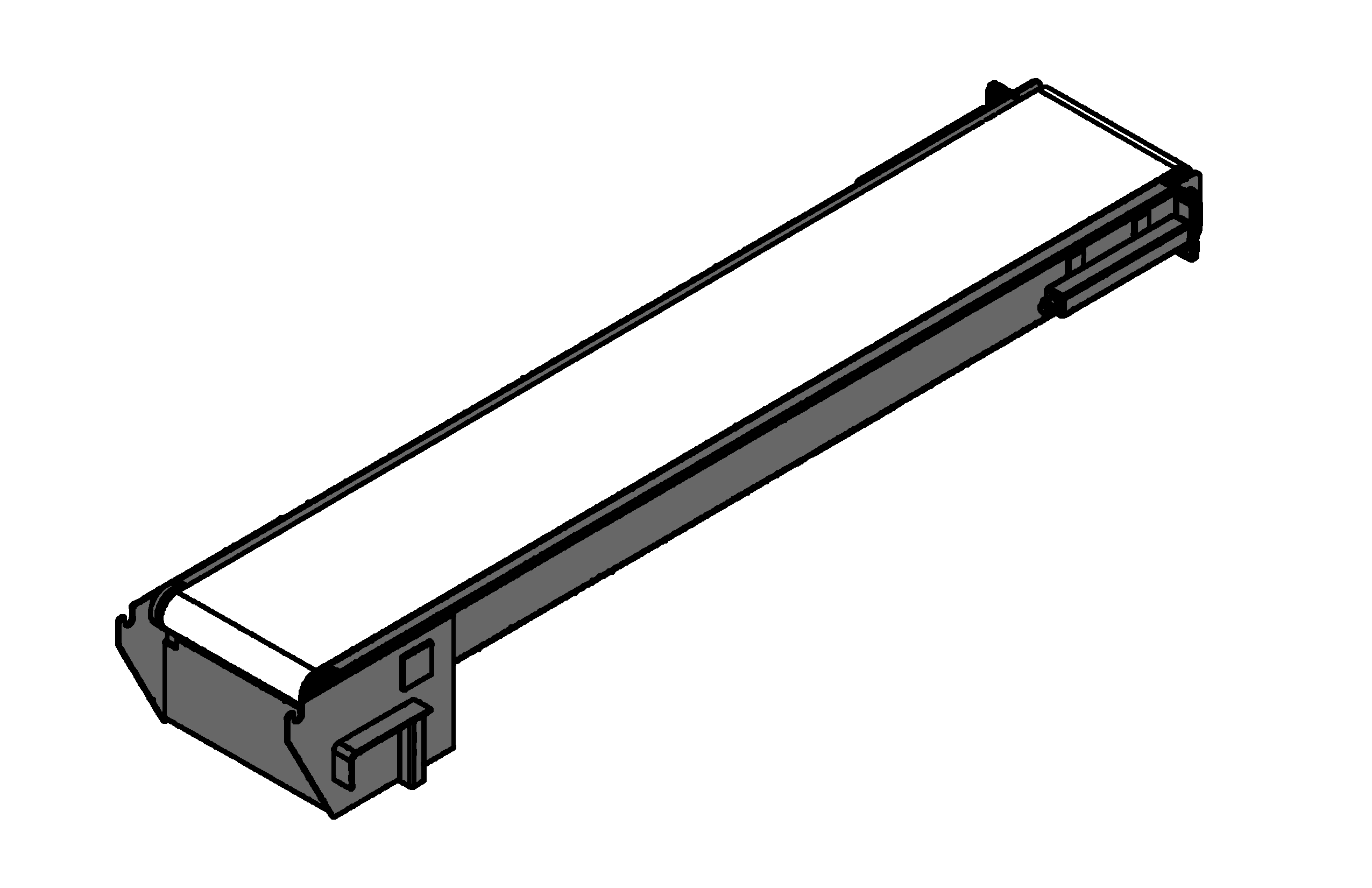

| 2200A Water Tunnels |

| 12"Wide X 5'8" Long | |

| Powder Coated or Stainless | |

Please reach out to us to learn more about options and to help you decide which piece of equipment is right for your application. Additional options may be available that are not listed here and specifications above are subject to change.

3 gallon including labor and rice hull material

3 Year, Unlimited Hours Warranty – INCLUDED

Includes: Problem identification, remote trouble shooting of issue, support and instruction for proper repair, and providing replacement of failed parts.

Excludes – Misuse of equipment (including using non horticultural potting mixes with high sand and field soil content) or improper care, such as leaving fertilizer in machine for an extended period of time. Wear parts (chain, slats, wear plates or surfaces). External physical damage inflicted on the machine. Labor repair costs.

Yes, we keep inventory of most all parts. Most all of the components are either US Sourced or a common off the shelf component. We are having some supply chain issues on components, but we are working through the best way to manage that.

All of our machines are designed right here in the US. We design these machines to be easily repairable by an inexperienced worker. Should a problem arise, you won’t need to weld or fabricate a new part. The entire machine is bolted together and you can simply bolt in a replacement part.

We have heard that concern, I get it, you won’t be able to load a machine up and let a person pot plants for a day.

Some perspective – The rear load machine holds about 3/4 – 1 cubic yard which is up to about 200 gallons of material. That gives you about 15 minutes of runtime without stopping.

The reason for the smaller equipment size is to primarily keep the price and complexity down.

-Increase horsepower requirements which means increased power – now you have to have dedicated power for the machine.

-Increasing the hopper size also increases the physical size of the machine which increases the overall cost and reduces portability

You may have not made a purchase on a potting machine in the past because of the overall cost.

From time to time, we hear that our production rates appear slow. Look at it this way though. You have 5 or 10 workers running a high-speed line. SOMETHING GOES WRONG, you now have all these people standing around and/or you need to find a different job for them.

If you have a machine problem with a high-speed line you’re completely shut down. With a cell-based design, you have a small part of the potting operation down. Your efficiency is similar whether you have 1 or 4 people operating STILT.PRO machines.

Help shape our future and be the first to know about new products