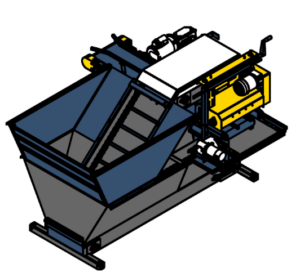

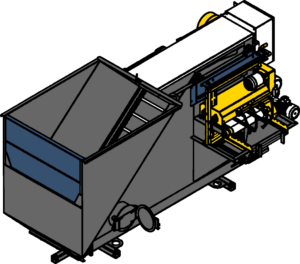

A-Line Model: The A-Line model is a budget-friendly, highly versatile, and efficient system that operates seamlessly with a compact 1 to 3 person crew and offers flexible hopper sizes of 1/3 and 1 yard. With production rates of 300 flats per hour or 12 gallons per minute, this robust unit handles everything from standard flats and trays to large 20-inch containers without requiring any machine changes. Convenient optional accessories include hopper extensions, simple manual tray sweep system, smooth-rolling casters, and durable wheels for towing.

Features:

- Advanced soil feeding for greater capacity

- Variable filling speed to match your production requirements

- Versatile, fills flats, pots and baskets

- Recycle and reuses excess potting media

- Steep slopes on hopper for better soil feeding